mAbs scale-up: Success at every step.

Every step along the path to full-scale monoclonal antibody (mAb) production is critical and must be carefully chosen to avoid interruptions or delays. From the very beginning, we work with you to design an agile scale-up process using the right materials, systems and components for your specific mAb environment. We’ll help you plan early to plan for success.

At Avantor®, we believe mAbs scale-up should be seamless, not siloed. You can rely on our technical expertise at every stage of development to customize a holistic manufacturing process for your unique mAb, using the right raw materials, tools and processes.

By adapting early to increasing volumes and more stringent regulatory requirements, we help you maintain consistent product quality and efficacy.

Our expert solutions for monoclonal antibody scale-up

Fluid Handling for Efficient mAbs Scale-Up

From small scale to large, our technical experts and engineers help you reduce bottlenecks and product loss with closed system fluid transfer.

Seamless mAbs Scale-Up from Research to GMP

We ensure a smooth transition from Research Use Only (RUO) raw materials to GMP grade, avoiding delays that could put your market entry timeline at risk.

Customized mAbs Buffer Management

Get set up for success with the right strategy to handle increasing volumes of buffers that meet critical quality attributes and improve process efficiency.

J.T. Baker® Viral Inactivation Solution

Improve viral inactivation efficiency and minimize introduction of impurities.

PROchievA™ recombinant protein A

Enhance your separation power and increase product purity.

Our Quality Promise

You can depend on our proactive risk management system to deliver the highest quality of GMP raw materials and fluid handling systems. Globally aligned quality standards, regulatory support and a robust supplier audit program ensure our products are compliant, compendial and traceable, so you can scale with confidence.

Our Consultative Approach

Our experts collaborate to design your entire scale-up process tailored to your needs. With our in-depth application knowledge, we integrate discovery, development, and delivery to support an efficient and agile mAbs process. Trust Avantor at every step so you’re not late to market due to disruptions or delays.

Our Global Footprint

Avantor's global network of cGMP and ISO-certified manufacturing sites provides a powerful channel and delivery system for critical raw materials and qualified fluid handling technologies. Transparent supply chain redundancy, as well as vertically integrated products and services, ensures scale-up success.

Learn More from Our Monoclonal Antibody Experts

It is essential to consider cGMP compliance early in development rather than waiting until late clinical trials and/or large-scale production. This article explores how using well-characterized, high quality and cGMP raw materials and reagents earlier in the transition to large-scale commercial manufacturing can avoid process changes, bottlenecks and delays.

To ensure the safety of biopharmaceuticals derived from mammalian cell culture, it is critical biomanufacturing processes can clear or inactivate potential viral contaminants.

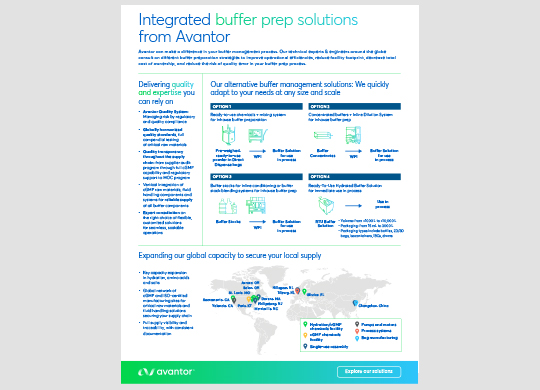

Avantor can make a difference in your buffer management process. Learn about our alternative solutions that we can quickly adapt to your needs at any size and scale.

With new diseases emerging at record rates, it is critical to be ready and able to respond quickly and scale up production efficiently. Whether you are looking for short term process improvements and large volume handing or long-term supply chain sustainability for GMP quality chemicals – we have your back.